RFID (Radio-frequency identification) has grown exponentially across all industry verticals to the point where the RFID market is expected to amount to $14.69 billion in 2026 at a 9.3% CAGR. At this point, it is clear that the technology will be around a common consumer for a long period in different forms. Therefore, this blog provides the ultimate guide about what RFID is and how it works.

Table of Contents

ToggleWhat is RFID (Radio-frequency identification)?

Radio-frequency identification, also known as RFID, is a wireless communication technology that is particularly used as a medium for proximity communication. To be precise, RFID is an electromagnetic communication method where RFID tags with digital data encoding are placed on objects or systems so that RFID readers can detect them uniquely for various applications.

RFID is versatile in its development and deployment. The majority of RFID applications are based on the innovative use of RFID tags and RFID readers. These tags are basically small electronic devices that can store minor data. RFID readers transmit EM power to tags to detect their presence by reading their unique information.

RFID can be useful for tracking different objects, controlling actuators, access control, exchanging information, and other such solutions. Furthermore, RFID tags can work with or without batteries in different sizes and materials. RFID tags are also available worldwide through varied manufacturers, ensuring longevity to products engineered with RFID.

RFID vs. Barcode: how RFID is better than its predecessor

Often, some industrial applications address RFID tags as smart labels. However, before the extraordinary adoption of RFID, printed codes such as barcodes and QR codes served many current RFID applications. Barcodes often serve the purpose of transmitting a small amount of information through an optical laser.

Printed codes made manual logs and label absolute as they cut down errors, costs, and brought technological efficiency to tracking and inventories. Almost every item that goes through supply chains interacts with barcodes, and the barcode market was worth $6.79 billion in 2020, even though the adaption of barcodes is really cheap.

Upgradation from Barcode to RFID is quite similar to how Barcode transformed manual logging. RFID systems are more accurate, sophisticated, quicker, and convenient than barcodes- keeping up with growing retail and industrial expectations. Here’s a detailed breakdown of the differences between RFID tags and barcodes:

| Barcodes | RFID tags | |

| Principal technology | Optical laser | EM RF waves |

| Propagation | Line-of-sight | Non-line-of-sight |

| Implementation cost | Very low | Low |

| Hindrances | Higher probability with wear & tear, dirty barcodes, etc. | Lower probability, only when dealing with metal or moist surfaces |

| Read/write | Read-only | Read & write |

| Scanning speed | One code at a time | Multiple labels simultaneously |

| Operation | Partially automated & human involvement | Can be 100% automated |

| Communication range | Lower | Higher |

| Maintenance needs | Constant | Timely to zero maintenance |

However, this comparison doesn’t necessarily mean that RFID is a complete rollover to barcodes or QR codes. Instead, these technologies together can create opportunities for perfect implementations where they can both add unique value.

What are some key benefits of RFID?

RFID applies an electromagnetic field to detect, identify, and track objects in the room. It offers a range of advantages over manual solutions or barcodes, as covered above. Here are some of the benefits of deploying it:

1. Being inexpensive

RFID tags can be cheaper for most applications and can serve any solution for a very long duration without needing any maintenance. Therefore, RFID solutions are inexpensive to implement, and some of them can even serve disposable needs.

2. Formfactor

RFID tags are quite small and thin and thus can fit into a variety of shapes and sizes depending upon the applications. Such flexibility allows brand and product designers to facilitate RFID over other wireless technologies.

3. Simultaneous readings

RFID tags can be read at once if they are within the range of the RFID reader, RFID reader antenna can broadcast radio waves and detect any active/passive RFID labels altogether, up to 100s of tags at a time. Therefore, making RFID an ideal choice for mass industrial applications.

4. Uniqueness

Each RFID tag is unique, so it eliminates any chance of counterfeiting in most user applications. Such unique identifier helps the implementer to track users, objects, access authorizations, purchases, and product lifecycle.

5. Secure records

With RFID, most of the identification and logging is made through a middleware program, and hence it eliminates any room for manual manipulations. Plus, only authorized parties can access the RFID information.

6. Automation

RFID readers can read RFID tags in any direction without Line-of-Sight communication. This allows RFID readers to be placed in a way to detect any RFID tags within close proximity automatically, making it ideal for manufacturing, supply chain, and retail businesses.

7. Robust in any environment

RFID tags can withstand any kind of environment without compromising their ability and performance. Therefore, RFID solutions can become a reliable choice for volatile and dangerous environments where other technologies may have limitations.

Furthermore, the advantages of RFID solutions are not limited to these. RFID is also very easy to use, reprogrammable, and can offer a variety of specifications to serve different applications. These benefits make RFID a tempting choice for industrial and consumer implementations.

What can Tesswave do for you?

Tesswave provide 100+ antenna products and you can contact us for antenna customized solutions, get in touch with us today to get a Free quote.

Get an Instant Quote

Get a FREE quote and we will contact you within an hour

The working concept of RFID

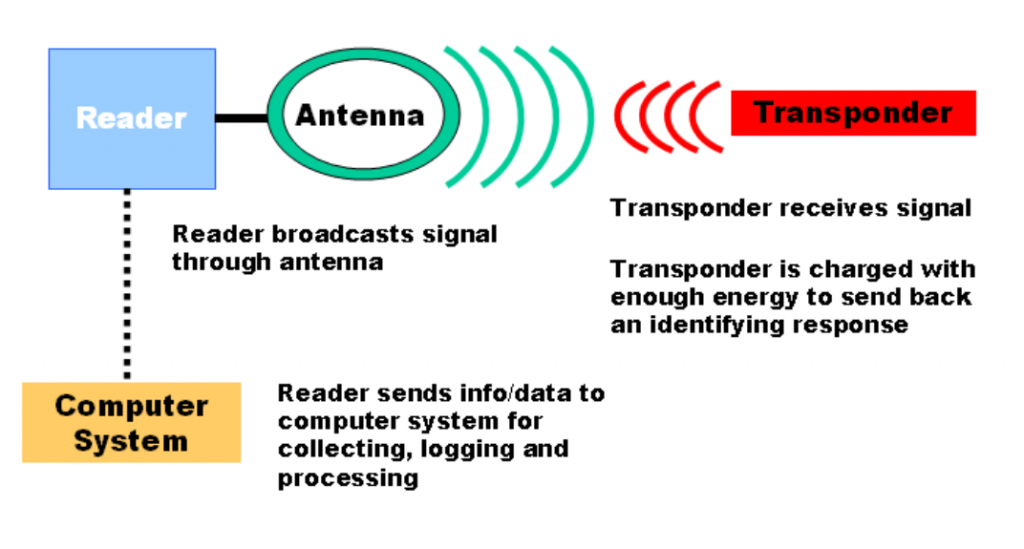

RFID solutions work on the principle of EM radio waves, and their working is slightly different in comparison to other wireless technologies. RFID systems work on the basic workflow as given below:

- RFID reader broadcasts radio signals to the surroundings

- Any surrounding RFID tag detects the radio signals and powers from those EM waves.

- Powered RFID tags send back a unique radio signal to the RFID reader.

- The RFID reader detects any such unique radio waves to decode the data out of it for unique identifications.

- RFID reader logs or records such detection into a software application or a basic database as per the user’s system solution.

What are the different types of RFID systems?

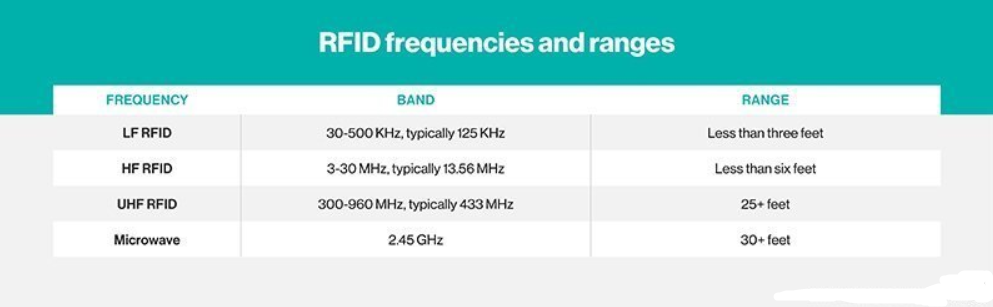

Different types of RFID systems can help further understand different implementations of RFID. Majorly, the use of various frequencies can help RFID solutions work in their unique characteristics. While every country has different standard operational frequencies, here is a general idea:

- Low-Frequency RFID:

Ranging from 30KHz to 500 kHz, Low-frequency RFID solutions cater to short-range transmission needs such as interactions on tap. They can serve unique RFID detection needs from a few inches to feet, depending upon their configurations. Typical average LF systems operate at 125KHz.

- High-Frequency RFID:

High-frequency RFID typically operates at 13.56 MHz and can range anywhere between 3 MHz to 30 MHz. HF RFID systems can support applications with a slightly higher range than LF systems up to several feet.

- Ultra High-Frequency RFID

Used often for industrial asset tracking, Ultra High-Frequency systems generally operate at 433MHz and can range from 300 MHz to 960 MHz, primary frequency is 433 MHz, 860-960 MHz. It can read across rooms beyond 25 feet.

- Microwave RFID

Microwave RFID or Super High-Frequency RFID systems can range even up to several hundred feet depending upon the system frequencies, anywhere between 2.45 GHz and 5.8 GHz.

These frequencies of RFID systems vary as per each country’s norms and policies. The above-mentioned data provides a general idea of different frequencies, their communication range, and potential applications of RFID systems.

RFID system architecture and building blocks

RFID systems are basically made of two major components RFID tags (RFID labels) and RFID readers. Every RFID reader is basically an RFID transceiver with an antenna to transmit RF energy. This energy can then be used to detect RFID tags based on the nature of the tags.

There are two kinds of RFID readers, including fixed readers and mobile readers. They both serve different applications as per the need for portability. While the types of tags and readers are crucial major parts, another key area is the software solution that is used as a user interface to log the RFID data and even visualize it as per the user’s needs.

To dive deeper, there are some more crucial elements that can participate in the performance of an RFID solution. Some of those parameters include the type of tags, frequency of operation, working environment, accuracy needed, other RFID tags in the vicinity, etc. The right engineering partner or supplier can help you figure out these system elements and make the right system architecture.

What can Tesswave do for you?

Tesswave provide 100+ antenna products and you can contact us for antenna customized solutions, get in touch with us today to get a Free quote.

Get an Instant Quote

Get a FREE quote and we will contact you within an hour

Different types of RFID tags and their use

A handful of RFID tags are available in the market that serves unique needs. RFID tags are often put into categories based on their operation, RFID frequency, material, etc. Here is a breakdown of some types of RFID tags based on their operation:

- Active RFID tags:

Active RFID tags are the type of RFID tags that carry a power source for itself inside the device. Active RFID tags come with a power supply and therefore do not rely on the receiver’s radio signals to power up and broadcast. Such tags are expensive, and typically high-frequency RFID systems need such an inbuilt power source.

- Passive RFID tags:

Passive RFID tags are the most kind of RFID tags available in the market. Such tags are cheap, compliant, and smaller to implement. Passive RFID tags can get the job done for proximity applications where a lower range is sufficient. They rely on the interrogator’s radio signals to power up.

- Semi-passive RFID tags (Hybrid RFID tags):

Semi-passive RFID tags are the middle-ground for active and passive RFID tags. Unlike passive RFID tags, these tags carry a battery for a longer range. However, they do not have an onboard transmitter like active RFID tags. Therefore, they have a range lesser than active RFID tags. It can be a right fit for sensing, tracking, and alarming applications.

In addition to these three types, RFID tags can also be divided based on their application and materials used, as given below:

- Liquid Resistant:

RFID tags can often be used for applications where they have exposure to liquids, whether for laboratory sample tracking or for laundry. As such, it is important to use the right RFID label protection that can withstand liquid exposure and work perfectly.

- Temperature Resistant:

Just like liquid, heat, or cold environments are a part of interaction when dealing with industrial machines/equipment. RFID tags can be made of the right materials to withstand harsh environments and even fire. Heat-resisting materials like Nylon, Teflon, or Ceramic can be excellent for protecting RFID chipsets.

- Metal surfaces:

Rugged industry-grade RFID tags are used to work on top of metal surfaces. These tags often use UHF so that the metal surface does not contradict the RFID system’s performance. Such tags are often made out of solid materials and can withstand mounting.

- Flexible tags:

As the name conveys, flexible tags can support textile or retail fashion products where the tag is made out of similar material and can bend and blend with the object perfectly. Flexible tags are often used in wearables and competitive sporting events.

- Printable:

For logistics and supply chains, printable RFID tags are the most beneficial type as manufacturers can print their own RFID labels at cheaper costs and get the perfect traceability of the item. Mostly made out of paper or plastic, these tags are quite inexpensive.

The most popular applications of RFID

RFID applications have scaled up quite quickly in some applications and verticals. Here are some examples of such applications:

- Inventory management

Inventory management has been a barcode-dominated sector where barcodes made manual log-keeping redundant and inefficient. Likewise, RFID can now make inventory management even more efficient with simultaneous readings and findings. Companies can now get real-time information about every type of stock that is available in the inventory accurately.

- Real-time indoor asset tracking

Real-time indoor asset tracking refers to the ability to find a particular object or equipment or even a person within the facility. Indoor asset tracking can only be feasible if the precise and affordable technology solution like RFID.

- Supply chain management

Supply chain quality management services can be transformed significantly with RFID implementation. RFID can track the product that is passing through different stages of supply chain management to find any productivity gaps or areas of improvement.

- Payment solutions

RFID-based payment solutions are among the most popular and widely used applications of RFID. LF RFID card can be used to link to a user and measure their spending or transactions.

- Retail shopping solutions

Retail shopping solutions such as detecting the cart cost, automated checkout, counterfeit protection, and theft detection are several key RFID applications for consumers. These solutions can be completely automated with the help of the right RFID solution.

Comparing RFID vs. other wireless technologies

RFID is among the very few proximity or short-range wireless communication methods available on the market, close only to NFC. Other wireless technologies such as Bluetooth, UWB (Ultra-wide Band), or Wi-Fi are quite different in their implementation and workings compared to RFID.

The major difference between RFID and these technologies is that RFID is used just for identification, authorization, control, and tracking. On the other hand, wireless technologies focus on real-time communication and bidirectional data exchange.

Such long-range wireless technologies ask for much more power, investment cost, and bring massive communication range compared to most RFID solutions that are inexpensive, small, and power efficient. However, comparing RFID to Bluetooth or Wi-Fi is not an apple-to-apple comparison since these technologies can coexist and offer the best out of each technological platform.

Conclusion

It is safe to assume that such a growth of RFID makes it one of the most prominent and long-lasting wireless technologies to exist. Such popularity and adoption of RFID have made it an easy implementation with plenty of resources and suppliers. Contact us today to discuss your RFID needs and ideas.